Choosing the right chain of custody model for supply chain impact

For companies with complex supply chains, meeting deforestation-free commitments and regulations requires a balance of traceability and efficiency. ISEAL’s new guidance can help companies choose the right chain of custody approach.

While uncertainties remain about the final form the EU deforestation regulation (EUDR) will take, tackling deforestation risk is as relevant as ever, and getting the implementation of deforestation-free commitments right today is a strategic priority for responsible businesses.

The consultation phase and launch of ISEAL’s Chain of Custody Guidance attracted unprecedented interest, highlighting the widespread struggle to translate ambitious sustainable sourcing goals into operational reality along supply chains. For companies, the traceability challenge has gone from scoping and pilots to full implementation, requiring systems that function effectively in the complex world of global commodity trade.

The good news is that such systems already exist. Credible third-party sustainability systems offer established infrastructure for exchanging reliable data across complex supply chains, built on decades of on-the-ground experience and deep relationships with actors in the field.

ISEAL’s newly updated Chain of Custody Guidance can help companies find the approach that best meets their needs. The steps below provide a clear path from commitment to compliance – and the competitive advantage that comes with effective implementation.

Clarifying organisational goals and requirements

Any successful sustainability strategy starts with a precise understanding of what the organisation is actually committing to achieve.

For example, is the company’s goal to address land use change and incentivise more sustainable production in the regions that it sources from, or to prioritise deforestation- and conversion-free (DCF) sourcing at product level? The requirements for these goals are not the same, and the systems needed to support them differ significantly. The former might require interventions within production landscapes where deforestation is currently occurring, with success being measured by the overall reduction in deforestation and land conversion. The latter will require systems to trace products back and verify that they weren’t produced on deforested or converted land, and progress can be measured by the percentage of verified DCF material sourced.

To make this more concrete, the EUDR requires companies to implement robust due diligence to ensure commodities within scope aren’t associated with deforestation. It demands the collection of information such as geolocation coordinates, legal production assurances and risk information at the site of production; systems to trace deforestation-free material as it flows through the supply chain; and due diligence statements for each shipment into the EU.

Monitoring a company’s commitment to support DCF production generally doesn’t require this level of traceability. It may suffice to identify the main sourcing areas where deforestation occurs and provide information on the performance of programmes to reduce deforestation in that area. This doesn’t necessarily need to be linked to specific physical goods as they travel through the supply chain.

Understanding these requirements shapes everything from data systems to supplier engagement strategies.

Assessing traceability aspirations vs reality

The next critical step involves an honest assessment of what’s actually feasible given supply chain complexity and capacity constraints. That means balancing what would be nice to have with operational realities. It’s also important to watch out for potential unintended consequences of implementing traceability requirements. Here are just a few factors to consider:

Supply chain reality:

- Number of supplier tiers and geographic spread

- Local infrastructure capabilities in key sourcing regions

- Commodity transformation processes (mixing, processing, refinement, storage)

- Ability to pass the cost of traceability on to buyers

Capacity constraints:

- Current data management systems and capabilities

- Strength of existing supplier relationships

- Resources realistically available for implementation

- Regional team presence and local context understanding

Potential unintended consequences:

- Exclusion of small producers due to the higher cost of traceability per volume of goods sourced

- Disengagement with partners who can’t meet requirements, resulting in lost leverage

- Higher energy requirements for running parallel processing to enable traceability

- Data privacy issues.

Full traceability of physical goods and the sustainability information attached to them unlocks the ability to make specific and credible sustainability claims on a final product. But traceability should not be confused with impact – it’s a tool that can help to achieve an outcome, it’s not the desired outcome in itself. And sustainability impacts might be achieved without full traceability – at lower cost and potentially avoiding unintended consequences. Companies may even need to forego full traceability to be able to credibly demonstrate sustainability impacts – for example, if processing methods don’t allow granular separation of materials throughout the supply chain.

Choosing the appropriate chain of custody model

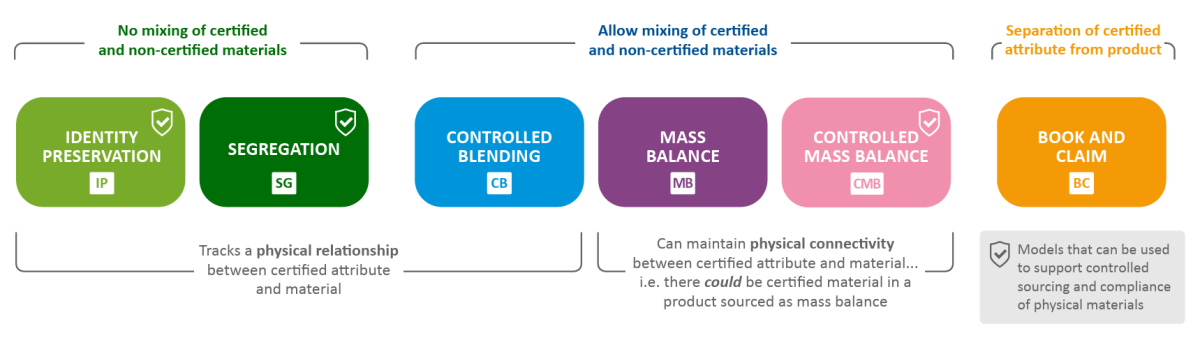

Once the sustainability goals and traceability requirements and limitations are clear, it’s time to understand which chain of custody model you need. Sustainability systems have well-developed models to track certified volumes and attributes. ISEAL’s Guidance describes six main models:

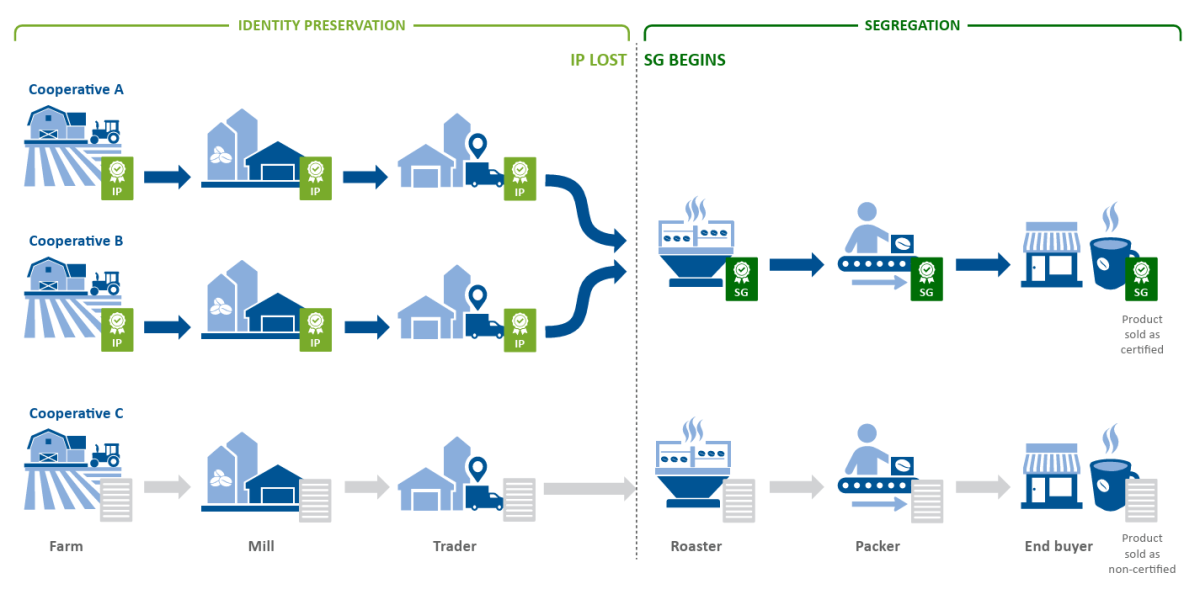

- Identity preservation/segregation: Segregation involves keeping products that meet sustainability criteria physically separate from others throughout the whole supply chain, enabling organisations to claim that the specific physical goods conform to these sustainability criteria. Identify preservation – segregates not just by sustainability criteria, but also by production source – is particularly valuable for premium products where origin traceability adds value, such as single-origin coffee or other products where consumers value specific sourcing stories.

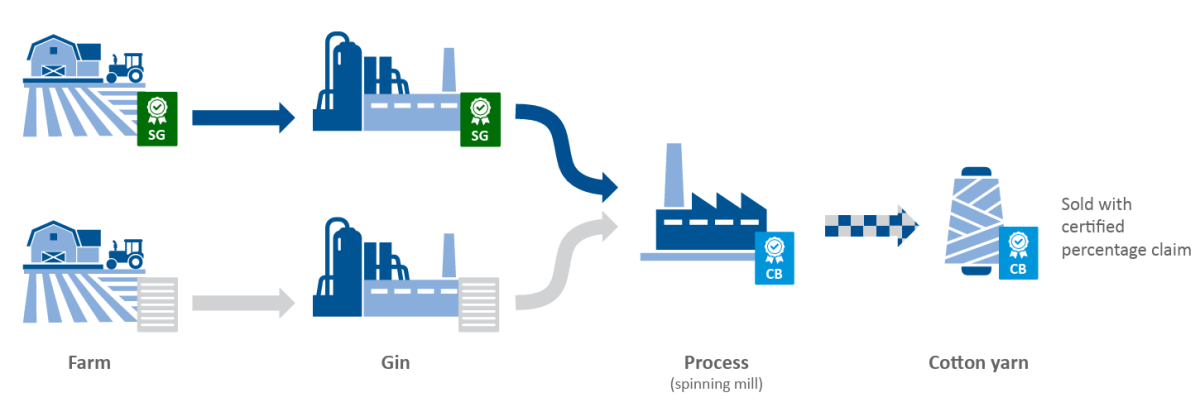

- Controlled blending: Here, the finished product contain a mixture of materials, but the proportion that meets sustainability criteria is tracked throughout the manufacturing process. The textile industry uses this extensively – precisely controlling ratios of cotton that conforms to certain sustainability criteria to conventional cotton in yarn production and tracking percentages through to finished garments.

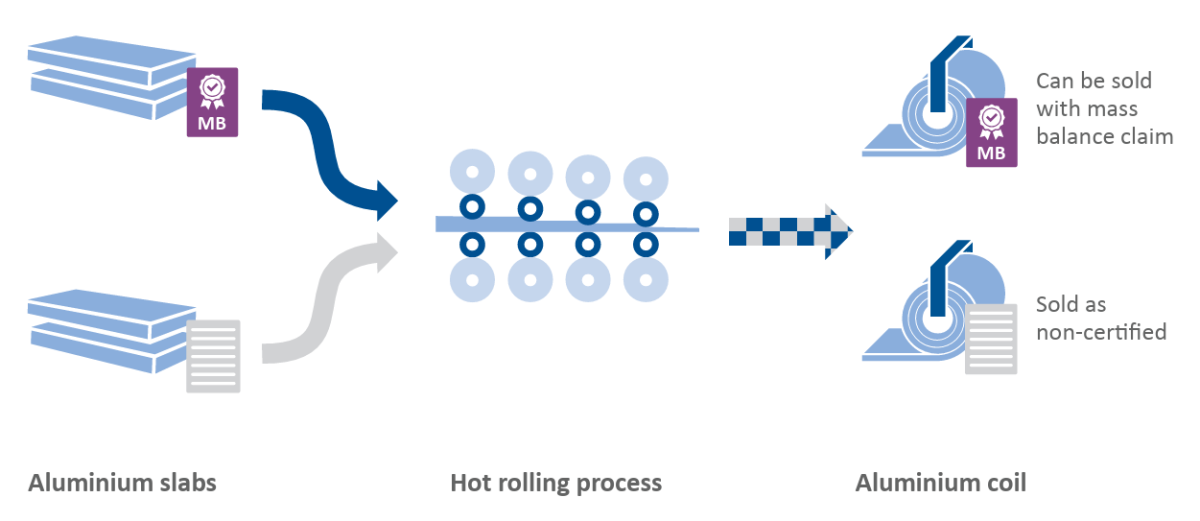

- Mass balance: The go-to solution for maintaining accountability when physical separation isn’t feasible. Total volumes of material that meet sustainability criteria are tracked through the supply chain but are mixed with other materials. Because it’s not possible to know how much of the material in the final product was actually produced according to sustainability criteria, claims focus on supporting sustainable production rather than containing sustainably produced material.

- Controlled mass balance: Here, all inputs must meet a minimum set of requirements, while volumes that meet additional sustainability criteria are tracked through the supply chain, as in a mass balance approach. In the context of the EUDR, this would mean all inputs are deforestation-free and traceable back to the site of production, but some also meet wider sustainability criteria. This hybrid approach can help companies comply with regulatory requirements while maintaining operational flexibility and supporting sustainability goals beyond legal compliance.

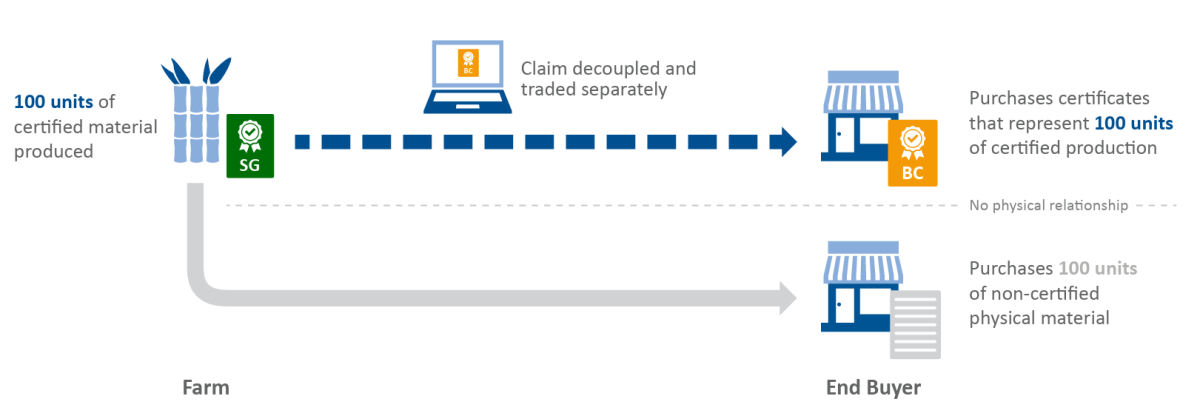

- Book and claim: Used to support sustainable production where physical traceability is impossible. Companies purchase certificates representing production volumes that conform to certain sustainability criteria, supporting producers who meet these criteria, while sourcing conventional materials.

Partnering with credible sustainability systems

Once you’ve chosen a model that meets your own needs, the question arises of whether to implement this in-house or partner with existing sustainability systems.

Standards and certification systems have years of experience working with complex global supply chains, the best available evidence of impact, and reliable systems for exchanging data essential for managing risk at scale.

Partnering with credible sustainability systems enables companies to achieve more than compliance – they build competitive advantage. Companies can access decades of experience and proven infrastructure, gain stakeholder credibility, and join networks providing ongoing intelligence about market developments, regulatory changes and emerging best practices.

The next steps are straightforward:

- Download ISEAL’s Chain of Custody Models and Definitions Guidance v2.

- Complete the requirements assessment honestly.

- Map potential partners against chain of custody model requirements, geographic coverage and regulatory requirements.

- Contact shortlisted sustainability systems to start the conversation.

ISEAL’s work on deforestation-free supply chains is generously supported by the Walmart Foundation.